LK 106MT Good Price Automatic Gold Hot Foil Stamping Printing Machine For Sale

1. The high quality Automatic Flatbed Golden Hot Foil Stamping Embossing Machine For Sale is designed for die cutting, embossing, debossing, creasing process.Changing mold fast, paper delivery, pull lay, paper feeding, positioning by one press, all automatic positioning will be done, together with the pressure adjustment mechanism to complete the work

of cutting.

2. hot stamping foil machine by electric control, paper feeding control, paper delivery control.

3. The automatic hot foil stamping machine is equipped with the automatic lubrication system.

|

MACHINE SPECIFICATIONS

|

|||

|

Model

|

LK 106 MT Automatic Die Cutting And Hot Foil Stamping Machine

|

||

|

Max. sheet size

|

1060*770mm

|

||

|

Min. sheet size

|

450*370mm

|

||

|

Max. die cutting size

|

1050*750mm

|

||

|

Max. stamping size

|

1050*750mm

|

||

|

Gripper margin

|

8-17mm

|

||

|

Paper Range

|

90 - 2000 GSM ( cardboard ) 0.1 - 2 mm ( cardboard ) lees than 4 mm (corrugated)

|

||

|

Max. cutting force

|

300 T

|

||

|

Max. mechanical speed

|

7500 S / H

|

||

|

Max. stamping speed

|

6500 S / H

|

||

|

Foil pulling shafts

|

longitudinal 3

|

||

|

Zones individually heated

|

12 heating zones ( each zone can be adjusted independently, the highest adjustable temperature is 200 degree )

|

||

|

Max. foil longitudinal diameter

|

250 mm

|

||

|

Max. delivery pile height

|

1200mm

|

||

|

Max. feeding pile height

|

1350mm

|

||

|

Main motor power

|

11 kw

|

||

|

Machine power

|

46 kw

|

||

|

Overall machine dimensions

|

6050*4200*2260 mm

|

||

|

Air requirements

|

0.6 MPA, more than 0.37 m³ / min

|

||

1. High quality electric parts

Over half of the machine electric parts use high quality international brand which could keep the machine in very good condition, running smooth and stable.

2. Strong metal machine body

A stronger body that made by high strength metal it could offer more capacity, that makes machine afford more cutting speed.

3. Control system with wireless network

Easy, smooth and friendly.

Our chief engineer could assistant and solve you by internet with no lag.

4. Automatic Paper Feeding with servo motor control

Tried about feeding paper by manual? Try our automatic paper feeding system, low staff cost, feeding full automatically, and controlled by high accuracy servo system.

5. PLC and Sensor

PLC that is short for “programmable Logical controller”, which could make sure that every working part gets perfect cooperation when running complex producing process. Most of them that we use for our machines is PANASONIC, MITSUBISHI and other international brand with WE!NVIEW touch screen. Also compare with the sensor from OMRON covered the machine body to keep safe of the equipment and operator.

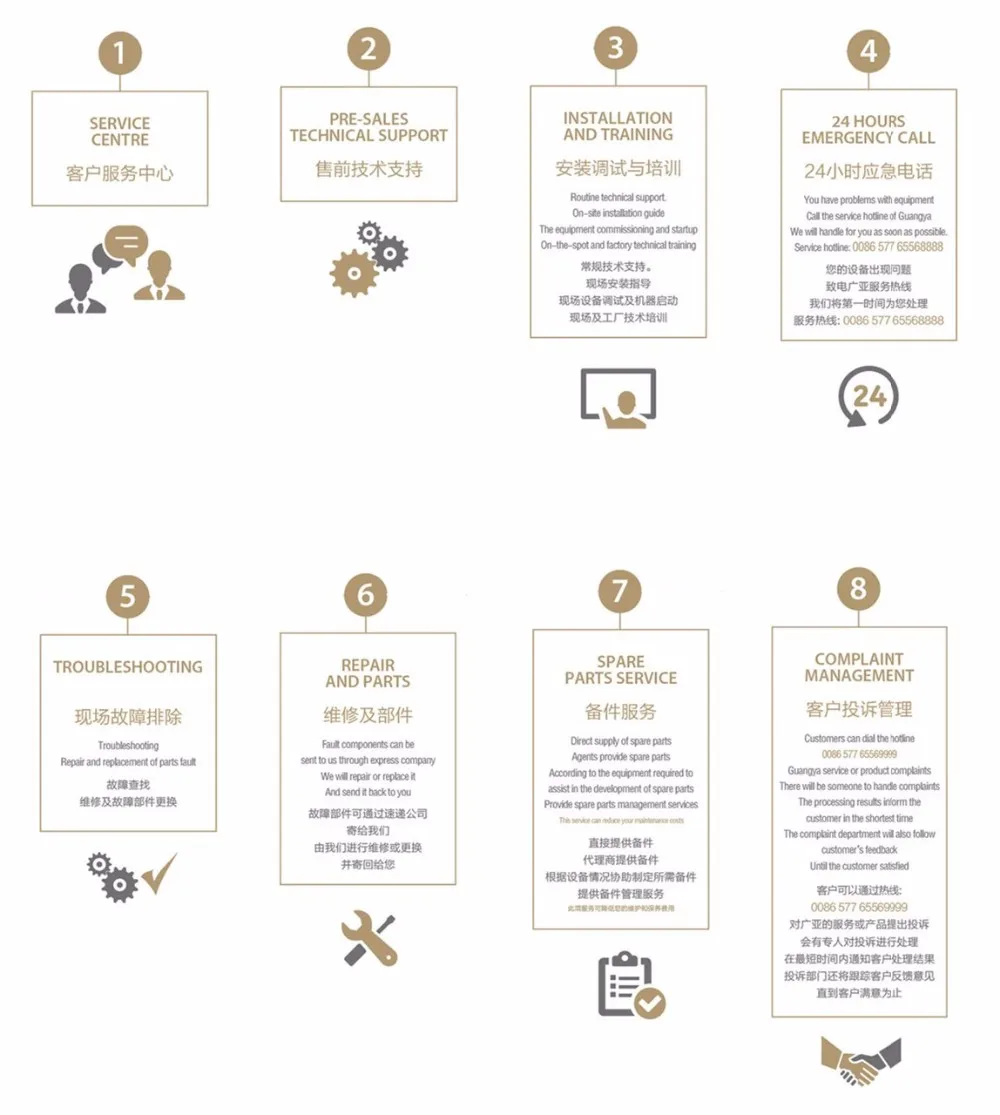

1.Installation And Training:

Routine technical support, one-site installation guide, the equipment commissioning and start-up , on-the-spot and factory technical training.

2.Trouble Shooting:

Troubleshooting, repair and replacement of parts fault.

3.Repair And Parts:

Fault components can be sent to us through express company. We will repair or replace it and send it back to ou.

4.Spare Parts Service:

Directly supply of spare parts agent provide spare parts according to the equipment required to assist in the development of spare parts. Provide spare parts management service.

5.Complaint Management:

Customer can dial the hot-line:0086-577-65569999

GUANGYA service or products complaints. There would be a engineer team that specially for after sales service.

Focus on Die Cutting and hot foil stamping machine since the year 1995, nowadays, our machines running in more than 80 countries.

We know much about what quality means, we care more about your feeling when using machine.

Quality make us business partner, trust make us friend.

We have been worked on the industry of die cutting and stamping machine as a manufacturer for more than 20 years and from now on, we would carry on to offer products with good quality to our customers as what we had done in the last two decades. Beside, it would also be our very honor to assistant our clients with other products if it is necessary.

Our company located in Binhai New Zone, Ping yang County, Zhejiang Province.

Transportation nearby.

Airport: Wenzhou Air port.

Railway Station: Ruian Railway Station, Aojiang Railway Station, Wenzhou South Railway Station.

30 to 35 Days after deposit.

Various Payments acceptable, normally T/T and L/C.

After-sales service could be the most important point that we should mention. However, every machine got full set testing process and adjusted in perfect condition before delivery, and, there are after-sales line which your could get reply in any time a day for it is 7*24h working time. And at last, we got a full team engineers that specially for overseas service and you would get full supporting from them if necessary.