Introduction:

Roll Feeding square bottom paper bag making machine forming the paper bag in one process from printed or unprinted roll paper , side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing, bottom forming, bag formation at a stroke. This machine controls by PLC programmable servo motor through the human-machine touch screen interface. It can produce various of specifications paper bags. This machine have advantages of high speed, quickly replace the paper bag specifications, more wide range adjusting etc. It is an ideal machine for producing food bag, shopping handles bag.

Features:

1. Material lifting adopt pneumatic lift structure.

2. Global initiative, leading technology, the real automatic constant tension control system, using the United States Bellofram constant precision pressure regulator, tension from start to finish no less.

3. Double photoelectric sensor limit automatic correction control system and deviation rectification stability, energy saving, long life

4. Adjustable into cylinder template synchro control structure, save template cost, easy and quickly adjustment.

5. Thumb buttons, appressed bottom cutting device, bag type have many choices.

6. Thumb mouth and appressed bottom cutting position does not stop cutting position synchronous adjusting structure, adjust the more direct, more convenient.

7. Don't stop machine adjusting indentation position structure, indentation position adjustment will be a very convenient things.

8. Don't stop machine clamp the wheel hub side, suction nozzle synchro control structure, adjust the side clips will become very simple and fast.

9. Don't stop machine adjust double bottom structure, the adjustment will become more intuitive, more simple,more time saving.

10. Glue roller air defense coating control, avoid gluing on besmear brushs hub surface directly, reduce unnecessary trouble.

11. accurate color tracking system, color errors automatically shut down

12. Automatic lubricating oil supply system

Technical Parameter:

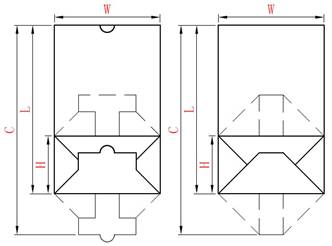

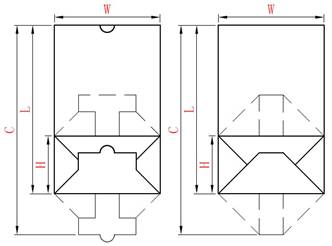

|

Type

|

LFD-350

|

|

Bag Width(W)

|

120-350 mm

|

|

Bag Length(L)

|

250-480 mm

|

|

Bottom Size(H)

|

70-150 mm

|

|

Bag tube length(C)

|

290-580 mm

|

|

Max.Speed

|

150 pcs/min

|

|

Paper Thickness

|

80-160 gsm

|

|

Paper Roll Width

|

400-1050 mm

|

|

Max.Roll diameter

|

1200 mm

|

|

Reel inner diameter

|

76 mm

|

|

Total Power

|

16.2 Kw

|

|

Weight of Machine

|

9000 kg

|

|

Overall Dimension(LxWxH)

|

8000×2150×1750 mm

|

Note:

Machine speeds dependent on paper & adhesive qualities, bag dimensions, operator knowledge, and general work philosophy.

Ruian Lilin machinery Co., LTD., is a professional paper bag machine manufacturer.It was founded in 2006, since its inception,the company has been committed to the r&d and production of paper bag making machine, constantly introducing new and high technology, combined with market demands and constantly develop new products, higher quality, higher efficiency to meet the market demands.

Lilin main products: LHB-450Fully Automatic Roll-fed Square Bottom Paper Bag Machine ,LSB-450Roll Feeding Square Bottom Paper Bag Machine, LSB-290Roll Feeding Square Bottom Paper Bag Machine, LSB-190Roll Feeding Square Bottom Paper Bag Machine, LFD-350 reel feeding square bottom paper bag making machine, LMD - 600 fully automatic high-speed food paper bag machine, LMD - 400 fully automatic high-speed food paper bag machine, LSY - 100 high-speed paper handle machine,these products have been sold to southeast Asia, Europe, Middle East, Africa, South America and other more than 30 countries and regions.

Since its inception, the enterprise always adhere to the "technology first, quality first" business philosophy, with honest and trustworthy operating style, excellent product quality and excellent service to win for the principle, for the user to achieve maximum value to reflect my value. Wholeheartedly welcome the domestic and foreign merchants to come to visit or inquire.